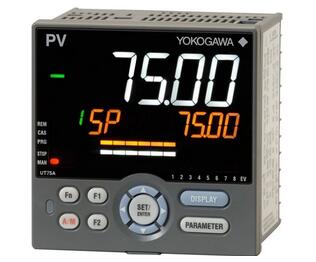

Advanced Application Temperature Controller UT75A

The UT75A temperature controllers employ an easy-to-read, 14-segment large color LCD display, along with navigation keys, thus greatly increasing the monitoring and operating capabilities. A ladder sequence function is included as standard. The short depth of the controller helps save instrument panel space. The UT75A also support open networks such as Ethernet communication.

UT75A Temperature Controller Features

Comes with a 2-loop control function

Ladder sequence capacity up to 1,000 steps

Includes custom ladder function

Offers 20 sets of target setpoints

Supports open networks (CC-Link, PROFIBUS-DP, DeviceNet)

The UT75A temperature controllers employ an easy-to-read, 14-segment large color LCD display, along with navigation keys, thus greatly increasing the monitoring and operating capabilities. A ladder sequence function is included as standard. The short depth of the controller helps save instrument panel space. The UT75A also support open networks such as Ethernet communication.

UT75A Temperature Controller Features

Comes with a 2-loop control function

Ladder sequence capacity up to 1,000 steps

Includes custom ladder function

Offers 20 sets of target setpoints

Supports open networks (CC-Link, PROFIBUS-DP, DeviceNet)

UT75A Temperature Controller

The Enhanced Peformance, Usability, and Flexibility Meet the Advanced Control Needs in a Wide Variety of Applications

Enhancing Productivity by Managing a Variety of Recipes

Switching between 20 Recipes

Increasing yield by managing a variety of recipes

Increasing quality in combination with 16 PID values

Program pattern operation

Program pattern consists of up to 20 segments

2-loop program pattern can be operated

Easy to switch between recipes with a PLC

Since CC-Link, Profibus, and DeviceNet are supported, it is easy to link to a PLC that manages recipes

Reducing Engineering Costs and Peripheral Devices

Simplifying ladder programs

Multi-line ladder programs such as numerical calculation can be turned into a single line using a custom ladder instruction.

This simplifies the ladder programs and facilitates easy engineering and maintenance.

Created custom ladder instructions can be saved in a file.

Custom ladder instructions saved in a file can be used by another UT75A temperature controller.

External calculators and sequence control circuits (relay, timer, etc.) can be reduced

Complex I/O offset calculation and alarm sequence control can be accomplished using a ladder program

Engineering costs such as wiring and initial setup can be reduced significantly

A sequence over 2 loops can be created for 2-loop control

Communication with a PLC is possible without using any program

CC-Link, Profibus, and DeviceNet are supported (optional)

Since communication with the PLC without using any program is possible, engineering costs can reduced.

Protecting Knowledge of Users

Protecting Knowledge of Users

Custom arithmetic expressions can be created using a ladder program

Multi-line ladder programs such as numerical calculation can be simplified into a single line using a custom ladder program

Custom ladder programs are securely managed using passwords

- Custom arithmetic expressions can be made inaccessible to protect the knowledge of users

Inheriting and Enhancing the UT750

2-loop control with a single controller

2-loop synchronous and independent operation is available

- The start and stop instructions can be run synchronously or independently.Program pattern operation and constant value operation are available for 2-loop control

- A sequence can be run by combining the program pattern operation and fixed-point operation.

A variety of arithmetic instructions and large capacity ladder programs

15 basic instructions and 111 application instructions

Ladder program capacity up to 1,000 steps

Advanced arithmetic instructions are available

Square root, exponential, and logarithmic calculations are available

Temperature/humidity and CP calculations are available

Reducing Downtime

Universal input and output

A single backup controller can be used for different control objects with different types of sensors and heaters/actuators

- The UT75A can flexibly respond to a failure and sudden specification changes.

Simple parameter setting and transition using an LL50A

Parameters can be set on other controllers just by copying them

Parameters can be set before mounting the controller to the panel

Parameters can be set without power supply for the controller