YSS1000 Setting Software

The YSS1000 setting software (hereinafter referred to as the YSS1000) is package software to configure the functions of the YS1000 series (hereinafter referred to as the YS1000) devices. Writing and reading of parameters and user programs of the YS1000, and PID tuning and monitoring of user programs can be performed through the use of communication.

The YSS1000 setting software (hereinafter referred to as the YSS1000) is package software to configure the functions of the YS1000 series (hereinafter referred to as the YS1000) devices. Writing and reading of parameters and user programs of the YS1000, and PID tuning and monitoring of user programs can be performed through the use of communication.

Parameter Setting Function:

A function to set parameters of the YS1000. Functions can be configured, and PID parameters, linearizer function table, scale, and constants can be set.

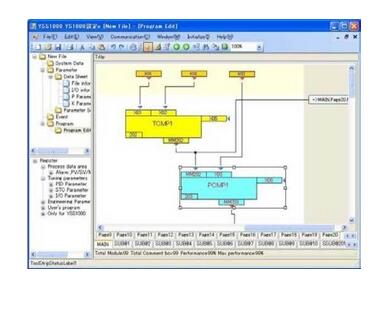

User Program Creation Function:

A function to create user programs of the YS1700. Programs can be created by selecting either function block programming or text programming.

Text programming enables programs to be created by describing operation commands in text format (Compatible with YS170). Function block programming enables user programs to be created by graphically linking modules.

Event Indicating Function:

A function to display a pop-up window with a message on the operation display of the YS1000 when an alarm is generated on the YS1000. This function is enabled by setting a parameter to trigger event indication and an indication message. (This function cannot be set on the YS1000.)

Japanese, English, and Chinese etc. fonts can be used to display event messages.

Communication Function:

Parameters and user programs can be written to the YS1000, and parameters and user programs stored in the YS1000 can be read out.

Note: Writing to the YS1000 can be performed only when the operation status is stop. (Reading can be performed without the need to stop operation.)

Tuning Function:

A function to adjust PID parameters of the YS1700 and YS1500 controllers. PID parameters can be set while viewing the PV, SV, and MV trend graphs through the use of communication.

User Program Monitoring Function:

Selected parameters can be monitored while communicating with the YS1700. When function block programming is selected, the input and output values of modules can be monitored on the function block screen.

File Management Function:

Set data such as parameters and user programs can be saved to a PC, and saved data can be read out from a PC.

Print Function:

Parameters and user programs can be printed with a printer connected to a PC.

YS100 Data Conversion Function:

A function to convert the data of the YS100 series to that of the YS1000. Parameters and user programs can be read out from the YS100 and converted to the data of the YS1000 (user programs are converted to text format). Furthermore, parameters and user programs created with the YSS10 and YSS20 program creation packages for the YS100 series can be converted to the data of the YS1000. Converted data can be manipulated as YSS1000 data; for example, edited, saved as files, printed, and written to the YS1000.

YS100 to YS1000 Data Conversion List

Data can be converted according to the conversion table below.

| Model before Conversion (YS100 Series) | → | Model after Conversion (YS1000 Series) |

|---|---|---|

| YS170 | → | YS1700 |

| YS150 | → | YS1500 |

| YS131 | → | YS1310 |

| YS135 | → | YS1350 |

| YS136 | → | YS1360 |

SLPC Data Conversion Function:

A function to convert the data of the SLPC to that of the YS1700. Parameters and user programs are read out from the user ROM of the SLPC and converted to the data of the YS1700 (user programs are converted to text format). Converted data can be manipulated as YSS1000 data; for example, edited, saved as files, printed, and written to the YS1700.

Check Support Function:

This function indicates check procedures for maintenance person by showing Check Operation Guide windows on the YSS1000 screen. The check result can be recorded in the internal memory of the YS1000 series or saved in the PC. It can be printed on reported format.

Main check items

Input / output check(X,Y,DI,DO)

Display function check(LCD, LED, operation KEY)

Hard manual function check Record of Model name, serial number, check date, checker

New graphic programming tool

Supports on-line module monitaring function

Program capacity

Supports 400 Blocks

Programming is easier with our intuitive function block programming.

The online module monitoring function allows you to confirm the performance while programming.

Original text based programming

Backwards compatible with existing YS170 users programs.

Increased programming capacity allows you to create more sophisitated control schemes.

Programming demonstration video

Sample parameter settings

Sample event messages

Programming in modular format

Text-based programming

Three connection modes

Connection modes: USB, Ethernet or RS485

When connecting via RS485 or Ethernet, a communication option is required on the main unit.

Full set of computation functions

Supports parameter setting for all YS1000 models

Support for YSS1000 custom programming.

Calculations done using Engineering units and Floating point math.

Includes over one-hundred computation modules for exponents,

logarithms, temperature/pressure correction, and other operations.Function blocks (sub-programs) can be saved and reused.

Password protection function

Passwords can be assigned to user programs to prevent unauthorized access to proprietary programs.

A password on the main unit prevents unexpected changes in the engineering parameters.